Seller's terms

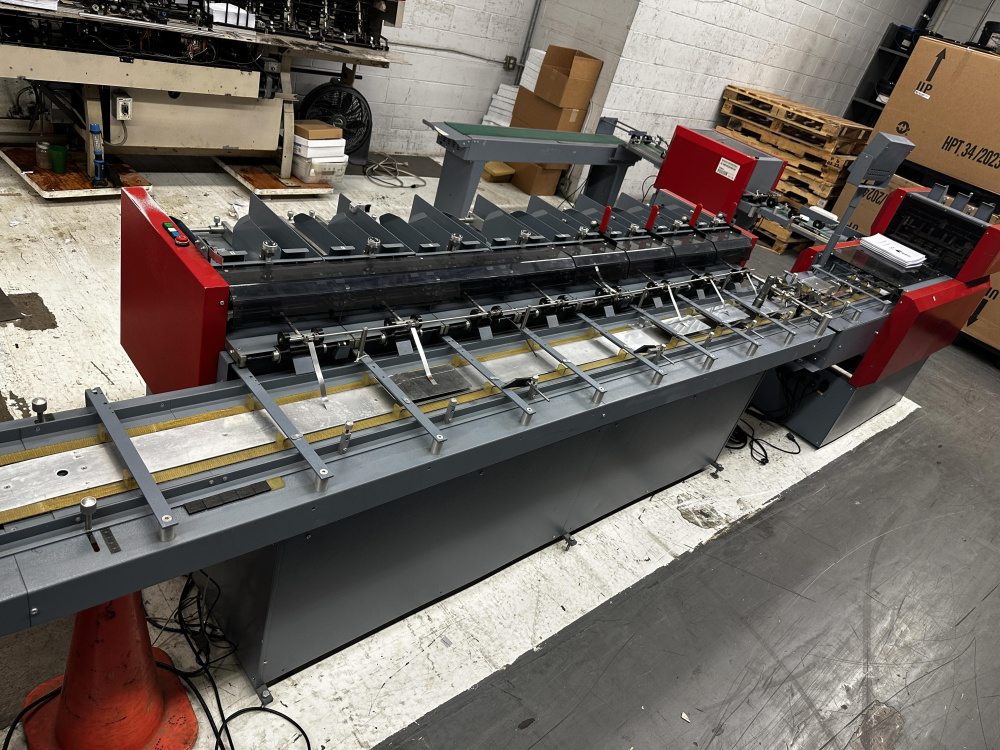

Lot #82: KAS Mailmaster 465HS Envelope Inserter

Sold by: Broudy Printing Inc. WireBids ID #WB84455

$10: $250 to $999

$50: $1,000 to $9,999

$100: $10,000 and up

You can specify the maximum amount that you're willing to pay for an item. When you're outbid, we automatically bid on your behalf up to your maximum bid. We increase your bid by increments only as much as necessary to maintain your position as highest bidder. Keep in mind we will prefill the bid amount for you with the next minimum bid increment (even when you are outbid).

Description

**** Reserve Price $1,600.00 ****

S/N: 025621

S/N: 025620

S/N: 025622

S/N: 025619

The Mailmaster 465HS Envelope inserter handles C4, C5 and DL envelopes, inserting at speeds of up to 6000 envelopes per hour.

It combines a unique design with proven technology, backed by over 50 years experience in mailing.

Designed and manufactured in Britain, this comprehensive modular enveloping system offers flexibility, durability and ease of set up.

Insert stations can handle a wide variety of material including single sheets, card, reply envelopes, pre-folded items, stapled sets, CD’s, plastic cards, and booklets.

It is possible to pre-select the number of items fed from an insert station, and have the feed switch automatically from one station to another when it runs low.

Fast Sheet Feeders can feed, accumulate and insert flat for C4, or fold and insert for DL and C5 according to codes read on the documents.

Our camera reading system adds more flexibility as it reads OMR, 1D and 2D barcodes in either orientation on the page. Jobs can be pre-programmed thus minimizing set up time.

Our reading technology facilitates batching the prime document, selection of inserts, merging and matching of two or more streams of personalized documentation, diverting of filled envelopes before sealing, envelope marking, document tracking and integrity checking.

An important feature of the Mailmaster 465HS is the remarkably quick changeover from one job to another that is possible, even to go from DL to C4.

A choice of touch screens are available that controls the machine operation. The screens give station selection, speed control, re-settable counter, help pages, output speed and error location display.

Job control and reporting software is available which provides further on screen run information, and facilitates job control, document tracking, data storage and reporting.

Performance

Up to 6000 envelopes per hour output

Quick changeover between jobs

Durable British construction

Packing thickness up to 15mm

Flexibility

Inserts into envelopes from DL to oversize C4

Side insert stations feed a wide variety of material up to 7mm thick

Multiple feeding from each insert feeder to a pre-set number or code-selected quantity

Hand feed position

Additional modular feeders

OMR, Barcode, 2D and OCR available

Ease of operation

Pivoting touch control screen provides run information, error location and help pages

Easy set-up and changeover

Top load feeders for ease of filling, without stopping the machine.

Envelope and insert feeder low level sensors

Station linking, to increase loading capacity

Output conveyor stacker

Accuracy

Error Divert facility

Unique insertion system positively guides the inserts into the envelopes

Insert stations have miss, jam and double detectors

Ultrasonic double detectors on Fast Sheet Feeders

Further sensors throughout to stop the machine in case of error

Test mode for running a trial insertion

Sequential start up/clear down

Choice of reading technology

Document tracking and output checking options

Other Features Available

Variable thickness booklet feeder

Choice of high speed cut sheet feeder/accumulators

Document accumulation and nest folding

Continuous forms cutter

In-line stapling and booklet making

Further hand feed positions

High capacity loaders

Job control software and data-log reporting

100% closed-loop integrity

File based insertion

Filled envelope divert

Seller's Terms

Buyer is responsible for all shipping costs.